This tutorial provides an introduction to the basics of piezoelectricity. This includes an introduction to the nature of piezoelectricity, and a description of the two main families of piezoceramic materials (hard doped and soft doped). In this tutorial, you will also be introduced to the constitutive equations as well as the properties of piezoceramic material at high field. You will also find a description of the thermal properties of piezoceramic material, as well as an overview helping you select a ceramic material.

Nature of Piezoelectricity

The piezoelectric effect was discovered by Jacques and Pierre Curie in 1880. The initial observation was the appearance of dielectric charge on a crystal proportional to an applied mechanical stress. Soon thereafter, the converse effect i.e. the geometrical strain of a crystal proportional to an applied electrical field, was discovered.

Basics on piezoelectric material

Piezoelectricity is the property of some materials to develop electric charge on their surface when mechanical stress is exerted on them. An applied electrical field produces a linearly proportional strain in these materials. The electrical response to mechanical stimulation is called the direct piezoelectric effect, and the mechanical response to electrical simulation is called the converse piezoelectric effect.

Different piezoelectric materials

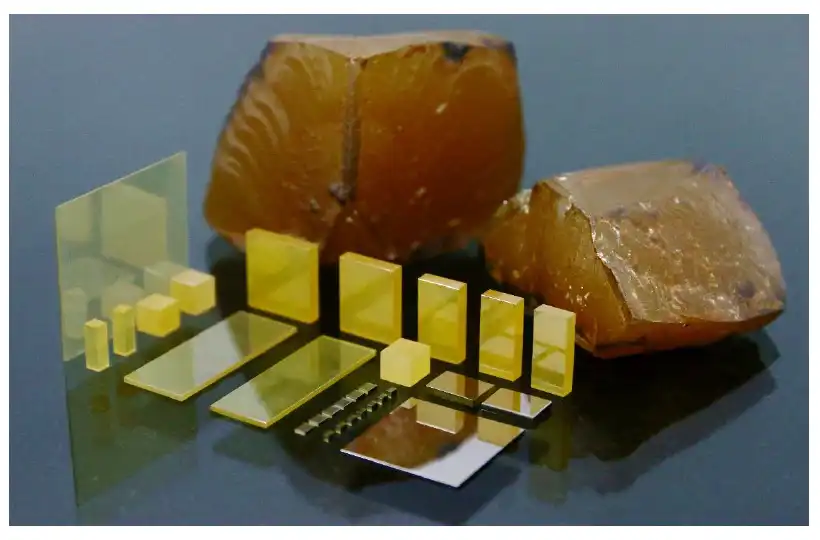

Piezoelectric effect is exhibited by most of the materials that possess a non-centrosymmetric crystal structure. Some naturally occurring crystalline materials possessing these properties are quartz and tourmaline. Some artificially produced piezoelectric crystals are Rochelle salt, ammonium dihydrogen phosphate and lithium sulphate. Another class of materials possessing these properties is piezoelectric ceramics.

In contrast to the naturally occurring piezoelectric crystals, piezoelectric ceramics are of a “polycrystalline” structure. The most commonly produced piezoelectric ceramics are lead zirconate titanate (PZT), barium titanate and lead titanate. Polycrystalline ceramic materials have several advantages over single crystal piezoelectric materials, including the ease of fabrication and forming of various shapes and sizes. In contrast, single crystals must be cut along certain crystallographic directions, limiting the possible geometric shapes, but offer superior piezoelectric properties, except Curie and phase transition temperatures.

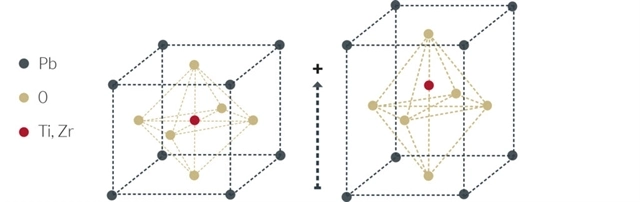

PZT crystal structure

PZT has crystal structures belonging to the perovskite family with the general formula AB03. In the following figure, the ideal, cubic perovskite structure is shown. PZT crystallites are centro-symmetric cubic (isotropic) above the Curie temperature and exhibit tetragonal symmetry (anisotropic structure) below the Curie temperature.

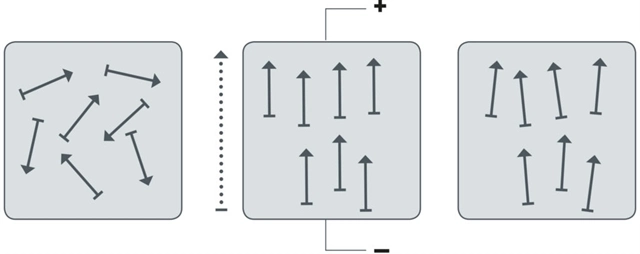

Poling process

Piezoelectric ceramics consist of grains (crystallites), each of these grains contains domains that are randomly oriented before poling, as shown in the left figure below. As a result, the net polarization of the material is zero and therefore ceramic does not exhibit piezoelectric properties. During poling process, adequate DC electrical field is applied and this applied electric field orients the domains in the electric field direction (as seen in the middle figure below) and lead to a remanent polarization of the material (as seen in the right figure below).